Ground Anchors

Geotechnical systems, Anchors, Anchors are always used in situations in which high tensile forces must be transferred into the ground. Typical applications include, for example, anchoring of excavation sheeting or retaining walls, slope and rock stabilization or anchoring for bridge abutments or wind turbine masts. Anchors, Strand anchors, consist of three main components: the anchor head, a steel tendon - divided into the bond section and free length - and the grout body. The steel tendon is constructed from a number of 7-wire prestressing strands.

Ground Anchors

Ground Anchors (also known as Grouted Anchors or Tie Back Anchors) are an active system (prestressed and locked off) that transmit applied tensile load into the ground. Due to prestressing, deformations are controlled - either minimized or eliminated. Ground Anchors are used for shoring next to existing structures in urban areas, rock & slope stabilization, dam construction, underground constructions and tiedown structures. Our ground anchor system complies with EN 1537, BS EN 1997-1 and BS 8081.

Ground anchor consists of three components; anchor head (anchorage), free stressing (unbonded) length and bond length. Anchor head transmits the prestressing force from the tendon (threaded bar or strands) to the structure that needs to be anchored. Smooth sheathing (bond breaker from the surrounding grout) over free stressing length ensures that the tendon elongates and transfers the resisting force from the bond length to the supporting structure. Bond length transfers the applied tensile load into the soil.

Based on design working life, ground anchors can be classified into temporary (up to 2 years) and permanent (more than 100 years). Tendons used in a ground anchor system are threaded solid bar and strands.

Selection of ground anchors shall be based on several factors such as accessibility, application, length of anchor, etc.

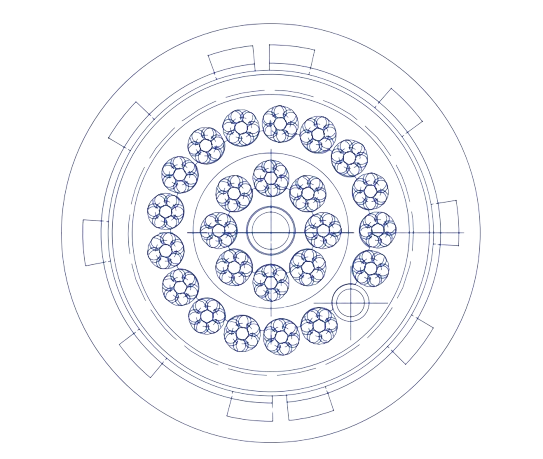

Strand Anchors

Based on service life, strand anchors can be classified as temporary or permanent strand anchors.

Temporary Strand Anchor: Temporary strand anchors are used for a service life of up to 2 years. Various configurations are possible based on site conditions and requirements.

Permanent Strand Anchor: For applications where service life is more than 2 years, permanent strand anchors shall be used. Complying with standards BS 8081 and BS EN 1537, permanent strand anchors consist of double barrier against corrosion. This is achieved by using individually PE sheathed greased strands in the free stressing length, single layer of corrugated sheathing over the entire anchor length and an outer layer of corrugated sheathing in the free length. On special cases, a second layer of corrugated sheathing is also provided in the free stressing length.

Anchor heads are available in restress-able type in addition to the normal anchorage. We can supply strand anchors fabricated using normal, super or compact strands.

Investigation Tests

- Conducted on trial anchors and tested to failure

- They identify the pullout resistance and thus allow for choosing a design load from the anchored structure.

- To ensure that the anchor is bonded into the strata in an adequate distance from the structure to assure its stability

On-site testing ensures the performance of the Anchoring System. This demonstrates both the quality and adequacy of the proposed design. Depending on the application, the appropriate test method should be chosen. Some tests may be more rigorous and are therefore conducted on sacrificial trial elements, installed as replicas of the working tendons. The testing of ground anchors generally involves three categories of tests.

Suitability Tests

- •Conducted on either sacrificial or working anchors to provide a data reference against which the working anchors can be measured

- •To document the ability to resist a proof load

- •To assess creep rate or load loss

- •To assess apparent free length parameters (the elastic part of the anchor)

Acceptability Tests

- •Conducted on working anchors to ensure construction methods and safety

- •To document the ability to resist a proof load

- •To assess creep rate or load loss

- •To assess apparent free length parameters